If you use a microscope or any other sample, raised from the work surface, the vertical flow hood will optimize the evacuation of particles from the point of use.You use large equipment on the work area – Less turbulence is when hitting large items within the flow is.You need larger workspace – there is greater width, depth and height available on the work surface.Choose a vertical laminar flow hood when: When your application requires the use of large equipment, Vertical laminar flow hoods have less turbulence and pushing particles down and away from the operators and work surface. You need better contamination protection.You are using small equipment that will not cause airflow disturbance.You need minimal turbulence on the work surface.Horizontal laminar flow hood is right for your work if: They are ideal for work with small objects and equipment.

When your application requires minimal turbulence and maximum contamination control, Horizontal laminar hoods are the best choice.

#A vertical laminar flow hood should be cleaned free#

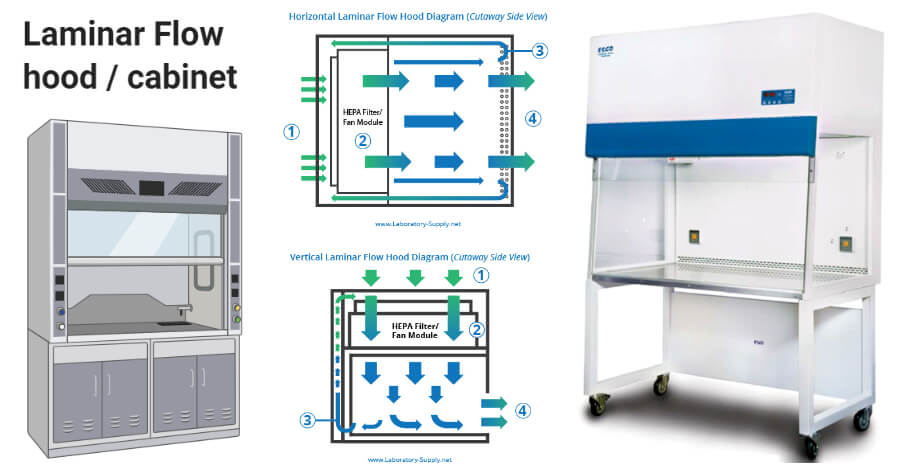

Horizontal and vertical laminar flow hood types have the same goal: to create free of particles and contamination environment to protect your product. Turbulent flow can be disturbing to work that requires a dust-free environment. The most important is to avoid creating turbulence around the material you are working with it. Vertical and horizontal airflow benches each have pros and cons when it comes to keeping objects contamination-free. Understanding the difference of each type could be essential for choosing the correct laminar flow for your application. the size of the area you are placing it.Which Laminar Flow Hood type to choose for your application?ĭeciding which laminar flow hood type to choose for your application can be difficult. Table top models control airborne contamination within a small space. They have underneath opening, which can be used for carts, trash, or storage. These models are space-saving and easy to clean.

The motor is placed under the work surface, which makes it easier to access.Removes air from under the work surface.Laminar Flow Clean Bench / Hood ModelsĬlean benches have a variety of sizes and styles to provide versatile solutions for clean-critical applications.Ĭonsole laminar flow can be vertical or horizontal airflow direction. The downward flow sweeps the particles outside of the enclosure through holes in the base and provides better contamination protection for the user. It removes particles just as horizontal laminar flow hoods, but turbulence may appear. This type of laminar flow provides the airflow over the entire work area, surrounding the object with clean, filtered air. Vertical Laminar Airflow hood / Clean Bench

0 kommentar(er)

0 kommentar(er)